Some Of Curtain Wall Spandrel Panel Detail

By understanding surface area temperatures, Pie is able to figure out under which problems condensation will occur, as well as recognize shift factors at which condensation will certainly not develop, making it much easier to forecast and remediate - nhbc spandrel panels. On top of that, different setups can be modeled to take full advantage of interior surface area temperatures. Setting up back pans into the spandrel infill glazing pocket, which are vented to the outside with insulation outboard of the frying pan, promotes enhanced indoor surface area temperatures with the added advantage of reducing heat transfer via the spandrel infill.

It is possible to take full advantage of indoor surface area temperatures by getting rid of using insulation at the spandrel infill place. Maintain in mind if you create without insulation at spandrel infill places, there will be a greater energy loss through the assembly as well as as a result larger HEATING AND COOLING warmth tons. At Pie, we can help you each action of the method, whether you recently found condensation as well as are seeking removal and management options, or whether you are creating a structure and also objective to decrease the possibility for condensation at spandrel infill places.

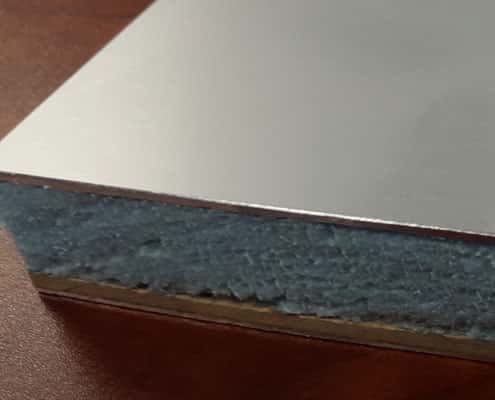

Improve R-Values Without Compromising Design! Polishing infill panels are created to be 'glazed' into an aluminum window system instead of glass. They offer lots of advantages to engineers as well as building proprietors searching for budget-friendly as well as cosmetically pleasing choices for their structures. Protected panels contain 3 various layers- a stiff insulation core sandwiched between a finished concrete face and back.

Utilized as a home window replacement, Synstone infill panels increase the thermal efficiency of window openings. This minimizes the price of possession by enabling cost savings on heating & cooling. Synstone infill panels contain non-asbestos glass fibre enhanced concrete faces with foam core insulation. Synstone infill panels can be made to R= 24 insulation value.

Nhbc Spandrel Panels Things To Know Before You Get This

In conventional building, the term "describes the roughly triangular space or surface area that is located between a rounded figure as well as a rectangle-shaped boundary. It is thought to acquire from from the Old French word 'spandre', meaning to spread out. Such can be discovered in a variety of circumstances: More just recently, the term 'spandrel panel' has actually been made use of to describe upreared triangular panels utilized in roof construction to separate spaces under the roof, or to finish the gable end of a roof covering.

The term spandrel panel may also be used to describe cladding panels that fill up the area over the head of a window on one floor as well as listed below the cill of the home window on the next floor on skyscrapers. These panels hide the floor structure. If they are made from nontransparent or clear glass, this might be described as spandrel glass.

It suggests that; "Spandrel panels can be given for both visual as well as practical functions. Like the rest of the exterior wall surface, the panels are typically required to fulfill acoustic, thermal, dampness, as well as fire efficiency needs. kawneer spandrel panel metal spandrel. Such panels are not typically load bearing but are typically developed to represent wind loading...

Where there is no info regarding the panel or there is uncertainty, it will be needed to examine the panel make-up by example testing." Ref https://www.gov. opaque spandrel panels.uk/government/publications/advice-for-building-owners-on-spandrel-panelswindow-panelsinfill-panels-on-external-walls NB The term spandrel beam of light refers to an exterior light beam that extends from one column to one more, bring an outside wall surface lots.

Glaz-Tech Industries introduces GlazeGuard 250WR and also GlazeGuard1000 WR infill panels to further give extra architectural options for storefront as well as window systems. Its sturdy as well as attractive layout adds with store applications and shielded units. Glaz-Tech's infill panels use numerous building advantages: GlazeGuard WR panels are very efficient against wetness intrusion and also perfect for setup because of its lightweight layout.

The Buzz on Roof Spandrel Panels

With a number of various make-ups and surface alternatives, GlazeGuard can give an economical alternative to various other polishing options while still supplying aesthetic rate of interest and value. Little or no upkeep is needed and most oil, dust, oil and opaque spandrel panels also other international material can be conveniently cleaned up from the surface. Glaz-Tech stocks Metal Silver, Shasta White and also Classic Bronze.

Element Criterion (in) Metric (mm) Prefinished Textured Aluminum Skins.010".254 mm Prefinished Smooth Aluminum Skins.024".609 mm High Thickness Polypropylene Core 1/4" 6.00 mm Building Requirement (in) Metric (mm) Panel Weight.72 lbs/ feet 3.51 kg/ m Small Density 1/4" 6mm GlazeGuard 1000 WR is a composite panel for use as a polishing infill made by laminating two prefinished light weight aluminum skins to substrates of high thickness polypropylene.